CHAPTER 4

DESIGN PROCESS FLOWS AND SOFTWARE TOOLS

The

purpose of this chapter is to:

- Describe the functionality of

design tools, both generic and those appropriate to a field-programmable

gate-array (FPGA)

- Describe some typical examples,

from start to finish, of design process flows, using manufacturer-supplied

cases. For simplicity only single-chip designs will be used at this stage.

We include schematic-based, behavioral-and floorplan-based examples.

4.1 THE

SOFTWARE TOOLBOX

Designing is a very exciting part of

engineering. Leaving aside formal definitions, it is the phase of engineering

where creativity and problem solving play the most important part. These

activities allow explorations of design options by trial and error, engineering

judgment, “guesstimation,” analysis, measurement, simulation, breadboarding,

and so forth. There is normally an overall strategy, however, to guide the

transition from specification to implementation, as discussed in

Chapter 1. What the engineer must do is flesh out

a complete behavioral, structural, and physical description so that a design

can be built and tested. With these often onerous tasks and informal

procedures, we can expect tools to “get in the way” of designing. The purpose

of this chapter is to be informative about the applicability of tools for FPGA

design and suggest fairly loose design process flows. The treatment is based on

taking a simple design example, the 7-segment display driver, through a

behavioral and structural design process. This example is conceptually simple,

but it is a nontrivial 4-input, 7-output function. It is also a standard

transistor-transistor logic (TTL) catalog part, the TTL7446. This serves to

emphasize alternatives in design process flows as well as highlighting the

relevance, or irrelevance, of specific tools.

This treatment is in distinction

to some more conventional approaches, mostly as found in manufacturers’

literature, which often portray the design process as a sequential walk through

a small number of design steps, yielding a perfect result every time.

Another source of confusion is

the plethora of tools available today. This is because the electronic CAD

industry has matured over the last 10 years into a number of sustainable

businesses (see

Chapter 7). The design bottlenecks of the

mid-1970s have been eliminated by structured design techniques embodied in new

tools and often the products of start-up companies. Today such companies are

mature and concentrating on marketing their products. The noise level is

rising, and it is important to be able to identify the functionality of a tool

to assess its relevance to FPGA design.

Table 4–1 enumerates tool types against design

description and level of design abstraction.

As a starting point, let us

examine the primary activities in designing. These may be termed design

capture, design validation, and physical design.

Figure 4–1 shows possible flows between activities

as well as tools that can assist in the processes within activities. Note that

the starting point for designing is the existence of a specification and that

the end point is the production of manufacturing data. Transitions in the flow

are driven by design refinement, yielding acceptable or infeasible designs.

Transitions to revise the specification are allowed.

Figure 4–1. Design process

flows.

Now in the case of FPGAs and our

example, to get into the flow we need a specification. The specification of a

7-segment display driver is intuitively obvious, given a labeling scheme for

the segments (see

Figure 4–2) and no performance or electrical

requirements. It could be, “drive the segments of the display to show the

decimal digits 0–9 from their 4-bit binary representation as input.” Well, how

do tools in a contemporary toolbox help, given this simple specification? The

following sections illustrate process steps.

4.1.1 Design

Capture

All design capture tools provide

functions for capturing design intent. They may capture structural intent,

behavioral intent, or both. They may be graphically based, for example,

schematics, or language based, for example, hardware description language

(HDL).

Figure 4–2. Labeling of

7-segment display.

Behavioral Tools Behavioral

tools address the question “what do I want this circuit to do?” Since the

behavior of a circuit is a mapping between a set of input states and a set of

output states, dependent on internal state (for sequential circuits), then

representations, such as truth tables, logic equations, and state descriptions,

are particularly useful. Truth tables are a perfectly simple and universal

behavioral description. The initial truth table for the display decoder is

shown in

Table 4–2. With the availability of programmable

array logic (PALs), several commercial behavioral HDL notations have emerged as

de facto standards: ABEL, CUPL, PALASM. The PALASM2 form of the same design is

shown in

Figure 4–3. For the established PAL families there

is even a standard file format for specifying fuse maps. In some cases these

can be interpreted as truth tables, but they are really a physical description

of features of a chip.

Synthesis If

behavioral tools only provided methods of describing circuit functions, then

they would be at least useful in refining specifications, assuming the

behavioral description could be animated. To take a first step to a real

manufacturable entity, however, a set of elements with defined behaviors must

be hooked up to make a circuit. Now if the behavioral semantics of these

elements are well understood, for example, in the case of logic gates, 2-level

logic blocks like PLAs, then it is possible to transform a behavioral

description into a structural composition of known parts. This is called synthesis.

Trivial examples would include interpreting a logic diagram as a behavioral and

structural design; mapping a set of logic equations into a PLA; decomposing an

HDL into a set of register-transfer-level interconnected elements. Optimization

is associated with synthesis and is applied to the automatic manipulation of

logic equations to yield an optimal, in some sense, logic-level design. Today

optimization and synthesis products are available from a range of companies.

Figure 4–3. PALASM2 HDL for

display driver. Figure courtesy of Xilinx Inc. ©Xilinx, Inc. 1989. All rights

reserved.

Structural Tools Structural

tools address capturing the design statement, “I think this interconnection of

units will exhibit the required behavior.” This is the more traditional design

metaphor, and it assumes the engineer is using knowledge of the behavior of

units, experience, judgment, and so forth, in making a plausible design

statement. Historically, this metaphor has always been supported by schematic

tools. In the case of the display driver, a schematic is shown in

Figure 4–4. This nonobvious design is structured

across three levels of logic. The top level drawing uses a left-to-right signal

flow convention.

Hardware Description Languages In

recent times HDLs like VHDL

[Mazor93] and Verilog have emerged as alternative

textual tools for design capture. Their present existence is based on work over

a long period of time to discover how to exploit the power of programming notations

in hardware design. In designs with repeated structures or conditional

structures, there are obvious advantages in using HDL descriptions, assuming

HDL compilers exist that can sensibly instantiate the design to a low-level

netlist form.

This type of HDL, compared to

the purely behavioral type, can be used for structural design and/or behavioral

design. The most common use is as a structural design tool to allow more rapid

generation of netlist data, that is, descriptions of interconnections of gate level

elements.

Figure 4–5 shows a VHDL description of the

schematics.

4.1.2 Tools

for Design Validation

Validation tools address the question

“what will this (structural) design do and how fast will it do it?” A broad

spectrum of simulator products, from circuit-level simulators, which solve the

underlying differential equations by numerical methods, to ad hoc

functional simulators in a high-level programming language, can be used.

However, with the emergence of component families at mediumscale integration

(MSI), large-scale integration (LSI), and very-large-scale integration (VLSI)

levels, logic level simulators have become the key design validation tools.

Since FPGAs by and large deliver gate level functions, logic level simulators

are particularly relevant.

Logic simulators are good at

answering the “what” question, at a cost in computer time. The “how fast”

question has been addressed by simulation tools in which time delays are

computed more accurately, such as by using RC circuit models in switch

level simulators. These have proved essential tools in getting full custom VLSI

designs to operate correctly the first time they are fabricated. Now with FPGAs

the computation of wire path delays can be complicated because the paths are

active in the sense that routing uses transistor switches and multiplexors. It

is infeasible to compute the behavior of FPGAs at switch level. Delays through

FPGA cells can, however, be modeled by a finite set of constants and path-delay

computations built into timing estimators. Since the performance of a circuit

is usually determined by a single critical path, estimator tools can replace timing

analysis.

Figure 4–4. Display driver

schematic.

Figure 4–5. VHDL for

display driver.

Our example is a purely

combinational circuit, and the design can be validated by applying the ten

legal input vectors and observing that the output vectors are consistent with

Table 4–2.

FPGA technology raises some

interesting questions on the relevance of validation tools. Simulation tools

have only gained users in recent times due to rising complexity in systems

design and difficulties in designing application-specific integrated circuits

(ASICs). Before simulation, systems were built on breadboards with standard

components and a rapid wiring technology (wrapping, Multiwire, etc). But FPGAs

can be used as instantaneous breadboards and synthesis programs create valid

designs algorithmically. The FPGA technology push is already creating more

interest in design methodologies. One can predict that areas like design

debugging will come under review now that equivalents to software debugging

techniques are available in hardware.

4.1.3 Tools

for Physical Design

Physical tools address the question

“how do I make this (structural) design fit physical reality while meeting

performance requirements?” All electronics technologies deliver finite spatial

resources for building functions and communications (wires). Resources are

especially tight with FPGAs, as the convenience of programmability is bought at

the cost of chip area for control store.

Conceptually the simplest tool,

and one that provides the essential handle on reality, is the graphical

editor. For FPGAs it is most likely to be a symbolic editor since it

is desirable to abstract away the underlying details of the silicon. The

figures in this book mostly show symbolic artwork of two FPGA families.

The physical design process can

be greatly assisted by automating the generation of random and regular logic. Block

generators for regular structures such as read-only memories and

programmable logic arrays are normally part of a software supplier’s package.

Generators can also be custom built by engineers using ordinary programming

languages. For random logic, placement-and-routing routines can be used

to build both random logic blocks and to assemble blocks at higher levels.

The total spatial demand of a

design includes a component for function units and a component for wires. It is

important to know early on if the spatial demand of a design can be met by the

spatial capacity of a particular FPGA. Estimator and fitter

programs assist in this task by computing function and wire demand for a

particular design for comparison with members of a standard part family.

The result of running standard

physical design software on the display driver example is shown later in

Figure 4–13. It shows a logic cell array (LCA)

implementation and two configurable array logic (CAL) implementations: one

using a ROM generator and synthesis program and the other handcrafted logic. It

exposes the eternal verity that humans can outperform algorithms, in this case

by a factor of 2, provided the design is tractable and there is sufficient

(human) design time.

It is likely the small example

we have been using is only part of a bigger design. In fact it was taken from a

VLSI class exercise in which the design specification is as given in

Section 4.4. In this case a key physical design

activity is

floor planning, in which the gross disposition of units in

the design and a wiring strategy for the design are defined.

Editors,

generators, and place-and-route programs can all assist the floor planning

phase.

Precooked designs are also a

useful source of tested designs with proven layouts. These are usually found in

supplier- or user-distributed libraries

[Newk83].

4.2 THE

FPGA DESIGN DICHOTOMY

One of the interesting properties of

FPGAs is that they merge what up until now have been two diverging families of

electronic products: programmable logic devices, notably PALs, and ASICs,

notably gate arrays and cell-based ICs. Each strand imposed a different

implementation style on the engineer, each came with its preferred design

process flow, and each came with its preferred toolset. The following sections

set out to show explicitly how FPGAs can be designed either from an ASIC or PLD

perspective.

Parenthetically,

it is too simple to suggest that only two design methodologies and toolsets are

important. In reality methodologies should be designed and toolsets chosen to

match the end FPGA application. For example, one could classify the chief

applications areas of programmable logic as: ASIC, ASIC emulation, and

algorithm implementation/coprocessing, in which case the following observations

would be relevant to method and toolset.

ASIC

Simple ASIC: A PAL design

methodology that places emphasis on tools for capturing a behavioral

description, optimizing logic equations and fitting the design to a member of a

standard part catalog.

Complex ASIC: ASIC design

places emphasis on both high-functionality tools for tasks like synthesis and

automatic place-and-route, and low-level tools for complete design control and

low-level optimization. More details are contained in the following sections.

ASIC Prototyping: The

assumption here is that the real implementation is probably a gate array or

cell-base IC (CBIC). So emphasis is in transforming a schematic to a netlist in

the most painless way possible. Automatic tools for physical design are key.

There is a desire for technology independence, but the preservation of

gate-level equivalent circuits may be a better design goal.

Algorithm Implementation: Algorithm

implementations usually exhibit some “natural” structure: cellular automata,

systolic circuits, self-timed micropipelines, pipelined coprocessors, dedicated

datapaths, and so forth. Emphasis is on the very efficient design of a basic

unit using low-level tools like symbolic editors and structure compilers.

4.3 DESIGN

PROCESS FLOW: THE PROGRAMMABLE LOGIC DEVICE ROUTE

A typical programmable logic device

(PLD) design process flow is shown in

Figure 4–6. The starting

specification

might be informal and hand drafted in anything from an HDL to a collection of

Boolean equations.

Design capture moves the design into the CAD

environment and requires the engineer to restate the creation for machine

consumption. This might be preparing a file in a preferred notation or marking

entries in a table.

Synthesis and optimization uses algorithms to

manipulate the logic design to improve it by exploiting don’t care states to

minimize the number of gates used.

Function verification may be a

unit-delay simulator to generate circuit outputs, or may amount to a manual

inspection of truth table data.

Device fitting matches logic/gate demand

and input/output (I/O) demand to part family members. Finally,

physical

design produces manufacturing data, a binary stream, for programming

specific devices. This must be achieved by generating a layout of the required

circuit in the chosen FPGA cell and wire scheme. It may amount to running a

simple logic block generator or it may be placing and routing random logic

using manual and automatic software tools.

Figure 4–6. PLD design

process flow.

4.3.1 Conceptual

Design of Display Driver

In the case of a CAL design the

specification is given in

Table 4–2. The minimization of this table using

ESPRESSO

[Brayton84] is shown in

Table 4–3. Now this is a standard sum-of-products

form that we can expect to implement within an array of cells that allows a

two-level logic structure to be built.

In the case of the LCA

implementation, because there is no “natural” form for implementing a two-level

logic structure, designs must be created as fully instantiated (flat) netlists.

For the display driver design specified in the PALASM2 of

Figure 4–3, a netlist must be optimized by

proprietary tools to accommodate implementation in configurable logic blocks

(CLBs) and the result merged with a top-level schematic to create the complete

design.

4.3.2 Design

Verification of Display Driver

In the case of the CAL design, since

the logic was synthesized there is no formal verification step other than

informal inspection of the truth tables.

In the case of the LCA design,

the flat netlist of logic primitives can be exercised with a logic simulator.

The result of this for a

test pattern of the ten digits is shown in

Figure 4–7. Readers can manually construct the

digits from the output to confirm the correct functions are being computed.

4.3.3 Physical

Design of Display Driver

In the case of the LCA implementation,

the result of applying placement and routing algorithms to the merged netlist

is shown in

Figure 4–23.

In the case of the CAL

implementation, physical design can be automatic, as in the synthesized ROM

logic block of

Figure 4–21, or physical design can be place and

route (manual or automatic) from a suitable gate-level netlist. Using the

gate-level schematic of

Figure 4–4 yields the manual design shown in

Figure 4–22. The synthesized ROM is further

described in

Section 4.5.1. It is interesting to compare the

quality of the logic synthesis with that of a manual implementation generated

with software design tools. The configurable logic ROM implementation requires

an 11 (4 inputs plus 7 outputs)-by-8 (product terms) array of cells compared

with an ll-by-4 array when implemented by hand. The following points are worth

noting:

Figure 4–7. Result of

simulating display driver.

- Flexibility. The

greatest advantage of the human-generated implementation is the way the

layout of the logic unit has been optimized to fit in with the chip

pin-out requirements and the counter design. Although there is a structure

to the layout (note that input variables are routed horizontally across

the array and outputs are collected using vertical wires), it is specific

to this particular example.

- Variable

Ordering.

In the automatically-generated array the order of the input variables in

the cascade of gates is fixed. Only the function performed by gates in the

cascade can be changed. The human implementation achieves a much better

factorization of the logic equations by changing the order of variables in

the gate cascades and using trees rather than simple cascades of gates.

This can only be achieved by having a special routing plan for each function

implemented.

- Design

Time.

Although the automatic implementation is much less efficient, it only took

about 10 minutes. The human-generated implementation took several days.

- Design

Size.

This example approaches the limit of the size of circuit which may be

designed efficiently by a person, and at this level of complexity, human

design may surpass automatic design. But for the most part circuit

optimization can be left to algorithmic methods.

4.4 DESIGN

PROCESS FLOW: THE APPLICATION-SPECIFIC INTEGRATED CIRCUIT ROUTE

There are many sources of ASIC design

process flows. VLSI design methodologies

[Mead80],

[Weste93] and ASIC manufacturers

[Naish88] are good sources. The former place

greater emphasis on layout issues, such as wiring management, to achieve

optimal physical designs, while the latter largely rely on structural design to

manage the whole process flow. A generic model for ASIC process flow is shown

in

Figure 4–8. Both the Gajski-Kuhn and more

traditional forms are shown. This indicates the refinement of a

specification

to a

structural design before entering design validation and physical

design processes. In reality the behavioral and structural descriptions are

built by stepwise refinement of the design. A typical ASIC design process flow,

represented by paths in the Gajski-Kuhn diagram, shows the three design

descriptions being built and the grain of the design unit decreasing. Thus a

starting behavioral

specification posits a

structural design.

This could be a composition of interconnected function units. This, in turn,

could be stepwise refined by expanding to a structural design of simple

elements, a gate-level netlist, or synthesizing a two-level logic block.

Figure 4–8. ASIC design

process flow.

To illustrate the flow let us

return to the display driver example. In fact, the 7-segment display driver was

part of a larger timer design exercise for a VLSI course. It had the

specification: Design a simple stopwatch to count in tenths of a second to one

minute and display the current time on three 7-segment displays (tenths,

seconds, and tens of seconds). The watch is controlled by three signals: INIT

clears the watch and puts it in the “stop” state, SS start/stop is a high-going

edge to start the watch from the stop state (a high-going edge in the start

state puts the watch in the stop state), CLOCK, a 10-Hz signal.

4.4.1 Conceptual

Design of Stopwatch

The 7-segment decoders provide a good

example of “random” combinational logic, while the counters provide a good

example of classic sequential logic. This design uses three separate units for

the three displays although the design complexity and area could be reduced by

implementing it as a single-state machine with multiplexed displays (since the

large 7-segment decoder logic would not need to be duplicated). This is

necessary to comply with the design specification given.

The Counter The

counter is built from four toggle flip-flops (

Figure 4–9). The basic 4-bit ripple counter is

converted to a decade counter by a gate that sets the clear line when the

counter gets to ten. The output of this gate is also used as the clock for the

succeeding counter. The counter can also be cleared by the user’s INIT signal.

Providing the clear capability is the only real problem in the design of the

toggle flip-flop (the basic D latches have only clock and D inputs). The clear

is provided by extra logic gates that force Os onto the D inputs and 1s onto

the clock inputs. A basic master-slave flip-flop can be built with only two D

latch cells, whereas this clearable implementation requires six cells. The

layout is shown in

Figure 4–10.

Figure 4–9. Toggle

flip-flop design.

The Decoder The

decoder takes advantage of the ability to produce any function of two Boolean

variables within one cell and uses three levels of logic rather than the

two-level logic normally used to implement such functions. Its schematic

description is given in

Figure 4–4 and physical design in

Figure 4–22 later.

The Control Logic The

controller function (at the bottom left of

Figure 4–11) is implemented using a toggle

flip-flop. The design is the same as those within the counters. The toggle

flip-flop is clocked by the start-stop input and its output determines whether

the counter should be stopped or run freely. The initialize signal clears the

control flip-flop and stops the counter. The counters are stopped by ANDing the

10-Hz clock with the output of the control flipflop: thus when the output of

the control flipflop is 0, the counters clock inputs are held low, and when it

is 1 the counters receive the 10-Hz clock input.

Figure 4–10. Counter

design.

Figure 4–11. Full Stopwatch

design.

Figure 4–12. Stopwatch

floorplan.

4.4.2 Design

Verification of Stopwatch

See Problem 3.

4.4.3 Physical

Design of Stopwatch

The floorplan of the full watch

circuit is given below as

Figure 4–12 and the layout in

Figure 4–11. The floorplan is based on using three

sides of the design to make connections to each of the displays accessible and

the fourth side to get the control signals into the chip. Note that the

floorplan requires simple transformations, rotations, and mirroring of the

basic unit.

4.5 LIBRARIES

AND DESIGN IDIOMS

In a sense design is idiomatic.

Engineers can express designs in modes particular to a set of components at a

specific level of design abstraction, for example, register transfer elements,

or components particular to an implementation style for example, small-scale

integration (SSI), MSI, and LSI TTL

[TTL88]. If one adopts a bottom-up view of the

world, then large designs are viewed as made up from aggregations of elementary

components, usually gates. Since electronic logic by and large evolved from TTL

elements, designs are perceived as compositions of TTL primitives. History has

created a data base of collective design experience. This data base may be

mined to create new designs from old experience, provided a set of primitive

components exists in the new implementation style. This view has led the ASIC

vendors to reproduce TTL libraries for customers’ use in designing (see

Table 4–4). Alternatively, if one adopts a

top-down view of the world, large designs are composed from generic high-level

elements, such as counters, ALUs, and register files, whose specific features

are defined in the design refinement process. This view of designing has led

the ASIC suppliers to provide parameterized register-transfer (RT) and

processor-memory switch (PMS) level component libraries,

Table 4–4.

These hard and soft libraries

are equally valid ways of collecting design experience and making it available

to practicing engineers in tried and tested forms. Hard libraries try to

maintain historical certainty in the encapsulation and functions of their

elements. In a sense, they are fossilized design fragments that may limit the

optimality of complete designs. Soft libraries can provide “made to measure”

components for optimal designs at the expense of variations in performance for

particular instantiations.

4.5.1 Parameterized

Libraries

It is often very useful to think of

library components as elements “sized” to a set of parameters: an n

input gate, an n word by m bit stack, and so forth. In building a

circuit the parameters are replaced by integer constants to suit the

application. A simple way of satisfying this requirement would be to fill a

library with all useful instantiations of a parameterized module and select a

particular one by indexing from the parameter. This approach allows for more

precise characterization of library elements at the expense of more storage. An

alternative approach is to use the parameters in a program to generate

the precise instance required. Two examples of this approach are described in

the following subsections.

Parameterized Modules The

requirement is to build a count “up-to-

n” circuit. A generic counter and

comparator, and constant generator, could be used to fit the requirement. The

alternative approach would be to compose a counter from stages, each of which

could test for a 0 or 1 depending on the position of these binary digits in the

constant. By adding comparator gates, see

Figure 4–13, to a basic toggle register we have

the elements for building a count up-to-

n circuit. The power of a

programming language can be harnessed to assemble such a part. We need to build

a vector of counter stages, each of which is conditionally defined. The

iteration and conditional selection features of a programming language are

well-suited to this task, provided there is a library of routines for

describing and instantiating cells. The fragment of C code shown in

Figure 4–14 shows this for assembling the

“onestage” and “zerostage” of

Figure 4–13. With

upto = 5, the

count-to-five circuit of

Figure 4–15 would be generated.

Block Generators: The

Configurable Logic ROM Generator With cellular FPGAs

there is likely to be a simple way of implementing a two-level structure. In

the case of CAL it is a configurable logic ROM. We will describe how it works

by first discussing a simpler but less efficient scheme.

Simplified Version This

version consists of an

n-bit decoder, an “AND” plane, producing 2

n-1

minterms feeding a special “OR” plane which uses two gate functions. As shown

in

Figure 4–16, the Algotronix CAL cell has four

inputs, one per side. Any two can be selected as XI, X2 for the evaluation of

an arbitrary Boolean function. The simplified CAL-ROM layout is shown in

Figure 4–17. If the row is selected, the cell

function depends on whether we require 0 or 1 output for this particular bit.

On the other hand, if the row is not selected, we simply pass through the input

received from the cell below, to take care of the case where the selected row

is below. If the selected row is above, the output of this cell is of no

consequence.

Figure 4–18 gives the CAL cell configurations.

Compact Version The

height of the array can be cut in half, and the decoder width reduced by one

cell. The last input variable is introduced at the bottom of each OR-plane

column, as shown in

Figure 4–19, and each cell in the OR-plane

computes a function of this variable and one of the minterms. If the row is

selected, the input from below must be AO. If the row is not selected, it may

either be below or above the selected row. In either case, it simply passes on

the input received from below—either A0 or the output of the selected row. The

cell function chosen depends on the value desired for A0 = 0 and A0 = 1, as

shown in

Table 4–5 and

Figure 4–20. The program

lisa automatically

generates this arrangement for a multiple-output function given an arbitrary

truth table.

Figure 4–13. Stages for

count-to-n circuit.

Figure 4–14. CAL operation.

Figure 4–21 shows the resulting layout of the CAL

cell array, in which the 4 inputs appear at the lower left hand edge, q3, q2,

q1, q0 and the outputs a,b,..., g at the upper edge.

Figure 4–22 is a manually-composed alternative,

with the inputs at the left and outputs at the right.

Figure 4–23 is a layout for a Xilinx XC3020 design

using the logic schematic given in

Figure 4–4 as input.

Silicon Compilation The

examples in this section of parameterized modules and generated blocks have

shown physical synthesis from high level descriptions. The term “silicon

compilation”

[Gray79], has been applied to this process. In the

case of the counter modules, the start point was a number of schematics for

count cells, and a C program was designed to compose the cells to form the

function. Because the start point for this process was a structural

description, the C program and (software) library functions represent a

structure

compiler.

In the case of ROM block

generator, the start point was a truth table, so the process was behavior

compilation and the synthesis software represents a behavior compiler.

Figure 4–15. Count-to-five

circuit.

Figure 4–16. CAL cell.

Note: the output is a function of the West (× 1) and South (×2) inputs.

Figure 4–17. Simplified

CAL-ROM layout.

Figure 4–18. CAL cell

configuration.

Figure 4–19. Compact

CAL-ROM layout.

Figure 4–20. CAL cell

options.

Both examples show the power of

silicon compilation techniques in generating substantial design fragments

quickly and with guaranteed structural integrity.

Figure 4–21. Physical

designs for the display driver: ROM-based CAL design.

4.6 PLACEMENT,

ROUTING, AND WIREABILITY

An eternal requirement in CAD tool

provision is for automatic place and route, preferably with 100% guaranteed

success and with a short run time. Unfortunately, placement and routing takes

place within the context of a real design and physical reality imposed by one or

more FPGAs, the implementation medium. Any design contains a demand for wires

with its point-to-point connections and bus structures. Since the FPGA contains

a finite number of wires, all FPGA architectures have a defined wiring

capacity. When there are gross discrepancies between the wiring demand of a

particular design and the wiring capacity of the target FPGA, it is likely to

be difficult to discover an implementation by any method including advanced

placement and routing algorithms. It is worth trying to understand the

relationship between wiring capacity and demand so that better engineering

decisions can be made about the suitability of a particular FPGA for a

particular design.

Figure 4–22. Physical

designs for the display driver: manual CAL design.

4.6.1 Rent’s

Rule and Package Pin-outs

Rent’s rule was originally

“discovered" from examining packages of logic modules

[Russo71]. It attempts to answer the

question, “How many connections (

n) are required to a structure holding

a number of components (

N) each of which has a number of connections (

m)?”

(see

Figure 4–24). The relationship can be

stated as

n ≈

m *

N(l-p), where

p

is Rent’s coefficient (≈0.5). It has an intuitive explanation if one imagines a

square array of components on a board. Cutting the board in half, creating two

edge connectors, would expose

m wires. The rule can be applied as a

“sanity check” on components that deliver random logic, like FPGAs, which are

made of

N logic cells with

m pins contained in packages of

n

pins. To make the most use of an FPGA while implementing random logic, the

ratio of user I/O package pins to connections to the logic cell should be

according to Rent. This exercise is left to the reader to be applied to the

commercial offerings at any point.

Figure 4–23. Physical

designs for the display driver: LCA design.

4.6.2 Rent’s

Rule and Wireability

Heller et al.

[Heller78] were the first to attempt an

analysis of wiring demand, in this case for logic designs in the context of

gate array “images.” They addressed questions such as: What characterizes

useful gate array architectures? How big should wiring channels be? What is the

average interconnection length of wires? What is the distribution and number of

interconnections? Simple one- and two-dimensional models (see

Figure 4–25) can be used. This shows three

terminal logic elements communicating with a wiring channel of fixed capacity

(the capacity in the two-dimensional case is the sum of the horizontal and

vertical wiring channels). By using Rent’s rule to compute average wire length

and making an assumption on the distribution of wires, it is possible to

estimate a channel capacity that will allow the interconnection of a given

number of logic elements. This is shown in

Figure 4–26. It shows that even for

relatively low gate counts, the ideal channel capacity is high, but as the gate

count grows logarithmically, the channel capacity grows linearly. The analysis

also covers variation for

m terminal logic elements. The result

indicates that to help the wireability of a design, the FPGA architecture, or

structures built from it in the case of channelless arrays, should support

channel capacities corresponding to gate count as in

Figure 4–26.

Figure 4–24. Two levels of

physical hierarchy.

Figure 4–25. Idealized

wiring models.

Figure 4–26. Variation in

wire demand with gate count.

4.6.3 Partitioning

Designs within and across Chips

Partitioning is important in three

areas:

- Partitioning

the resources within a single FPGA to support multiple designs

- Partitioning

a design into subsystems for placement onto regions of an FPGA

- Partitioning

a very large design across more than a single FPGA part

An example of the first case is shown

in

Figure 4–27. In this case, each of the

subsystems is self-contained and can be designed in isolation. There are at

least two important design decisions: can the subsystems be fitted onto the

chip? and does the pin-out make sense at the board level? It is likely that

there is more than one choice of implementation of each subsystem, and that in

the

parcel packing problem, in laying out the chip, the modules may have

alternative shapes. This degree of freedom can be important in making feasible

designs. The second question can only be answered in the context of the board

design and involves matching the wire demand of the chip pin-out to the wire

capacity of the board (defined from the copper dimension design rules and

number of interconnect layers).

In the second case the need for

partitioning comes from a requirement to divide a large design into subunits

for implementation, the traditional divide and conquer approach to engineering

problems.

Figure 4–27. Multiple

designs on a chip.

PROBLEMS

1. Find a simulator and simulate

the display driver design from the logic.

2. Verify

Table 4–2 as a correct behavioral

description.

3. Verify the same logic block by

developing expressions for the outputs evaluating these expressions for the ten

binary constant inputs.

4. Simulate the whole design of the

stopwatch.

5. Comment on the overpinning or

underpinning of some commercial FPGA parts.

6. Describe a wiring strategy for

building random logic within a cellular FPGA consistent with wireability rules.

CHAPTER 5

CASE STUDIES

The

purpose of this chapter is to:

- Illustrate the stages in

transforming a problem definition into a working solution

- Provide illustrations of

typical design tools

- Show the usefulness of

hierarchy

We

have deliberately chosen elementary examples, which for the most part only use

a small portion of a field-programmable gate array (FPGA) chip, apart from the

final example of the videostore controller. The problems have been carried out

with Xilinx and Algotronix FPGAs, using CAD tools obtained from these companies

and ViewLogic Inc. Since CAD software is regularly improved, and command

sequences change, any detailed information on particular CAD tools would

probably be out of date by the time this book is published. We recommend that

you obtain the latest editions of data books, user guides, and so forth, from

the companies or their local distributors. At the end of the chapter there are

suggestions for projects you might like to try for yourself.

The

Xilinx examples have been developed for a generally available demonstration

board, which is shown in Figure 5–1. It has eight switches for input, eight individual

light-emitting diode (LED) displays for output, and a 7-segment numerical LED

display. Some of the examples have been devised to fit this restricted set of

circumstances.

Figure

5–1. Xilinx demonstration board.

Photograph courtesy of Xilinx, Inc. © Xilinx, Inc. 1991. All rights reserved.

(Photograph by P. Crockett)

5.1 COMBINATIONAL

CIRCUITS

5.1.1 Parallel

Adder Cell

The simplest form of parallel adder is

a

ripple adder, which consists of a cascade of 1-bit full adder cells.

Each cell has inputs

A, B along with carry input

C. It produces

outputs SUM and CARRY, determined by the Boolean equations for a full adder,

corresponding to the truth table shown in

Table 5–1.

SUM = A... + Ā.B. + Ā..C

+ A.B.C

CARRY = A.B + A.C

+ B.C

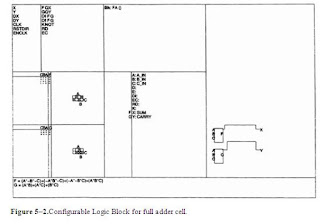

Xilinx Implementation The

equations may be entered directly as the

F and

G outputs of a

Xilinx 3000 series Configurable Logic Block (CLB), since each output can be an

arbitrary function of up to four variables chosen from a total of five inputs.

Since the functions are implemented by look-up tables, there is no advantage in

manipulating the equations further. For such a simple case it is easy to enter

the details directly on the CLB array with the editor

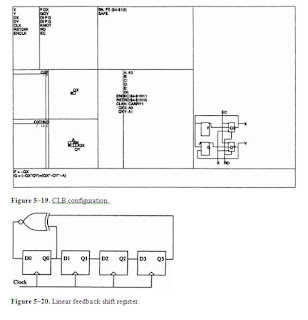

XACT. Figure 5–2 shows the block concerned, while

Figure 5–3 shows the routing to input and output

pads. The routing was determined by

XACT after each net had been given

as a list of pins. The configuration of each input or output block can also be

specified with

XACT, in this case direct inputs and outputs. The design

details were saved to a file to be used as input in generating a configuration

bit-stream file for downloading to the chip itself.

Alternatively, a schematic

diagram for the adder may be entered as a logic circuit, as shown in

Figure 5–4, which was prepared with the editor

ViewDraw.

This was used to generate a netlist, that is, a file specifying the logic

elements used and how they are interconnected. The netlist can be used for

functional simulation with a simulator such as

ViewSim, as shown in

Figure 5–5. Since the design has not at this stage

been mapped to an actual FPGA, this is only a functional simulation, and there

is no useful timing information. Translation to an actual Xilinx configuration

will be deferred until we have a more substantial example.

Algotronix Implementation Since

the configurable array logic (CAL) block functions have two inputs, the

equations need to be reexpressed:

SUM = (A ⊕ B) ⊕ C

CARRY = (A.B) + ((A

+ B).C)

The 1-bit adder can be laid out in a

block of 3 × 3 CAL cells as shown in

Figure 5–6. The graphical editor

clare was

used for this purpose, and allows the user to specify the function of each cell

and routing to and through it. The lower left cell holds the datum for the

block. Note that the cell is arranged so it can be cascaded vertically, with

the least-significant bit at the bottom.

5.1.2 Parallel

Adder

We can assemble a ripple-carry adder

by simply cascading the full adder. We use a 4-bit example.

Figure 5–2.Configurable

Logic Block for full adder cell.

Figure 5–3. CLB array for

full adder cell (XACT).

Xilinx Implementation Figure 5–7 shows a schematic prepared with the

schematic capture program

ViewDraw. There are four instances of the full

adder cell referred to in

Section 5.1.1. To use it with the demonstration

board, we need a top-level schematic, which is shown in

Figure 5–8. This shows the specific input and

output pads, which are connected to the dual-in-line switches and LEDs,

respectively. Again, the design may be simulated at this stage, that is, at a

functional level, and

Figure 5–9 shows results of applying a set of

input vectors VA, VB resulting in the output vector VSUM. The process of

converting the design into an FPGA implementation requires the following steps:

Figure 5–4. Schematic for

full adder cell (ViewDraw).

- Derive

a netlist from the schematic editor. This specifies the circuit in logic

detail, still in terms of idealized elements.

- Map

the logic circuit to the particular technology of the Xilinx 3000 series

CLBs, and input/output blocks (IOBs). This is a complex process, since

each CLB can generate two output signals, and the aim is to reduce the

total number of CLBs required. At the same time, some simplifications can

be made, for example, redundant logic can be removed.

- Placement,

which starts from a random assignment of CLBs to positions in the logic

array. For this design, the IOB positions are predetermined by the

demonstration board. The initial placement is evaluated in terms of

estimated wire length, based on the connection points of each net. The

placement is improved with an iterative process known as simulated

annealing, which moves CLBs to reduce the estimated wire length.

- Routing.

Each net is connected according to the netlist, and uses the variety of

available routing resources: direct connections from a CLB to its

immediate neighbor, connections via switch-matrices, and long horizontal

or vertical connections. This process results in a file containing details

of the placement and routing.

Figure 5–5. Simulation of

full adder cell (ViewSim)

Figure 5–6. Configurable

array logic for full adder

- Bit-stream

generation. The bit stream specifies the “program” for the FPGA, that is,

the memory bits which control the function and internal connections of

each CLB, the settings of all interconnect switches, and the mode of

operation of each IOB.

The bit stream can be downloaded to

the demonstration board, and the design checked with switches and lights. Later

we will discuss a more systematic way of testing using random patterns.

Algotronix Implementation The

graphical editor

clare was used to create four instances, as shown in

Figure 5–10. Note that the cells cascade by

abutment. The design was placed on the Algotronix CHS2×4 board described in

Chapter 6, and was positioned in the northwest comer

so that signals could be applied and monitored easily.

5.2 SEQUENTIAL

CIRCUITS

5.2.1 Decade

Counter

This design was implemented for a

Xilinx 3020 FPGA with the aid of the ViewDraw schematic entry program,

the ViewSim simulator, and Xilinx software for CLB mapping, placement,

routing, and so on. The design illustrates alternative ways of creating a

decade counter:

Figure 5–7. Schematic for

ripple adder.

Figure 5–8. Top-level

schematic for ripple adder.

Figure 5–9. Simulation for

ripple adder.

Figure 5–10. CAL layout for

ripple adder.

- Using

a macro element for a synchronous decade counter functionally equivalent

to the 74160 TTL component

- As

a collection of gates and flip-flops

- By

direct entry to CLBs

Figure 5–11 shows the top-level schematic.

The demonstration board has an

RC controlled oscillator based on a

single configurable logic block. The GOSC macro, shown in the lower left of the

figure, produces a clock that runs at approximately 100 Hz when connected to

external

R and

C components through pins 12 and 14. Another pin is

connected to a dual in-line package switch that determines if counting takes

place, or otherwise holds the counters clear, depending on the signal COUNT_EN.

The oscillator is connected to the global clock GCLOCK, which in turn

increments the least-significant decade counter.

Figure 5–12 shows the schematic diagram for

the 74160 synchronous counter.

Figure 5–13 shows an encoded state machine

design. The next state (N) variables are determined from the present state (P)

variables.

Figure 5–14 shows the state machine for the

decade counter.

Figures 5–15 and

5–16 show the basis for the design, which

takes advantage of unassigned states that will of course never be entered, that

is, decimal 10-15, and assigns 0 or 1 depending on the resulting simplification

in the Boolean equations. For example, in deriving the least-significant bit N

0

of the next state, the box corresponding to present state , that is, “12”

(decimal) is assigned to 1 to allow the whole column to be taken, and later

combined with the right-hand column as

0. The fifth D flip-flop is

used to delay the carry-out following state “9” until the next count pulse

arrives.

Figure 5–17 shows how the CLBs may be set

up directly by the user, that is, assigning their mode and Boolean equations to

be implemented. Note that the three alternative methods are shown for

illustrative purposes, and that in practice the 74160 macro method would be

preferred by most users.

The schematic information was

used to generate a netlist for use by Xilinx software, which first mapped the

logic to CLBs, and then determined a good placement on the 8 × 8 CLB array. The

routing was completed automatically, and the CLB array layout is shown in

Figure 5–18. The

RC oscillator CLB

is at site BA in the upper left. Note that after buffering by the clock buffer

it drives two vertical clock lines in the first two columns. Some connections

between adjacent CLBs are made by direct connection, which is fast, while

others pass through the much slower switch matrices, revealed by the sloping

routing. Each decade uses four CLBs.

Figure 5–19 shows the settings of a

particular CLB at location FE—this corresponds to the two least-significant

flip-flops at the left-hand side. Interestingly, the mapping process has

swapped the roles of the two outputs, presumably to reduce interconnection

delay, as can be seen by comparing the figures. The configuration detail shows

that both of the edge-triggered D flip-flops are clocked on a rising clock edge

(K), provided the clock is enabled (EC). The reset-direct (RD) signal is used

to hold the counters clear.

Figure 5–11. Top-level

schematic for 3-decade counter.

Figure 5–12. Macro cell for

74160 decade counter.

Figure 5–13. State machine

for decade counter.

Figure 5–14. State sequence

for decade counter.

5.3 PSEUDORANDOM

NUMBER GENERATION

Random numbers can be very useful in

simulation and testing digital circuits. Here we will use these numbers in

testing the parallel adder described earlier. The term

pseudorandom is

used because the process is in fact completely predictable. The linear feedback

shift register (LFSR) method is a particularly simple one, which can generate a

sequence of length 2

n – 1 for a register

n bits long,

provided it has the correct feedback connections.

Figure 5–20 shows a 4-bit LFSR that can generate a

sequence of length 15, not including the all-Is state, which is a

lock-up

state—once entered, the register will stay in this state indefinitely.

Table 5–2 shows the feedback connections to

produce a maximal length sequence for various register lengths.

5.4 RANDOM

TESTING

For large systems, random testing is

often a practical alternative to exhaustive, or case-by-case testing, and may

be built into integrated circuits and systems.

Figure 5–15. Equations for

state machine: state encoding for decade counter, less-significant bits.

Figure 5–16. Equations for

state machine: state encoding for decade counter more-significant bits.

Figure 5–17. CLB entries

for decade counter.

Figure 5–18. Configurable

logic block array for 3-decade counter.

Input patterns may be readily

generated with the LFSR method just described. Signature analysis is a

technique for compressing the resulting output patterns into a short word whose

final value indicates success or failure. While compression inevitably could

allow some circuit failures to produce an identical signature, the risk is

usually small.

We will take the 4-bit ripple

adder described in

Figure 5–4.

Figure 5–21 shows the top-level schematic.

Since there are eight input bits, along with carry-in, we will use a 9-bit

pseudorandom number generator. To compress the four sum bits and the carry-out

into 4 bits to be displayed on the demonstration board LEDs, we use a 4-bit

signature analyzer.

Figure 5–19. CLB

configuration.

Figure 5–20. Linear

feedback shift register.

5.4.1 Signature

Analyzer

The signature analyzer is an

adaptation of the LFSR. At every clock cycle, a set of outputs from the ripple

adder is loaded in parallel to an LFSR, with the feedback connections given

earlier. These are XORed with the previous register contents as shown in

Figure 5–22.

TABLE 5-2. LFSR Connections for

Pseudorandom Sequence Generation

Register

Length

|

Feedback

Connections

|

2

|

0,1

|

3

|

0,2

|

4

|

0,3

|

5

|

1,4

|

6

|

0,5

|

7

|

2,6

|

8

|

1,2,3,7

|

9

|

3,8

|

Figure 5–21. Top-level

schematic of a parallel adder.

Figure 5–22. Signature

analyzer.

Figure 5–23. State diagram

5.4.2 State

Machine

As discussed in

Chapter 2, state machines can be

implemented in different ways. Encoded state machines may minimize the storage

required, but at the expense of decoding logic, reducing speed. Here we use the

one-hot method, that is, one bit per state. The four states are as follows:

- Initial

state: wait for switch to be pressed

- Accumulate

signature from four output bits in signature analyzer

- Accumulate

carry-out bit in signature analyzer

- Display

4-bit signature on LEDs

Figure 5–23 shows the state diagram and

Figure 5–24 shows the schematic. Note that

State0 has inverting logic on both input and output, so that it automatically

goes high when the FPGA is powered-up. Also, the State3 output is used to reset

states 1 and 2 in the unlikely event of a logic state error, for example, if

either bit was simultaneously asserted with State3.

5.5 SYSTOLIC

SORTER*

This example is included to suggest

that FPGAs may provide novel ways of solving well-known problems. Sorting is

required in many computer applications, particularly commercial ones. Here we

look at a high-speed sorter, but one confined to miniscule amounts of data. It

is described as systolic because it uses a repetitive block structure,

and has a regular data flow. In general, each item to be sorted consists of a

number of fields, of which one is selected as a key, on which to sort.

For simplicity we regard the key as a nonnegative integer, and assume that we

wish to sort items in ascending order of their keys. For simplicity, we

concentrate on sorting the keys.

Figure 5–24. Schematic for

state machine.

Knuth

[Knuth73] distinguishes some basic sorting

methods:

Sort by insertion: Find the

correct place to insert an item in an already-ordered list

Sort by exchange: Consider

pairs of keys, and swap them if out of order

Sort by enumeration: Find the

smallest (or largest) key and remove the item to a new list. Repeat until the

original list is empty.

The scheme described here is a

combination of the first two methods. We assume that the items to be sorted

arrive individually, so it makes sense to keep previous arrivals in order—we

choose ascending. Borrowing a technique from full-custom VLSI design, we make

up blocks of cells, and arrange for simple connections of data and control

signals. The overall floorplan is shown in

Figure 5–25. Each key is stored in a

vertical column of one-bit blocks, with the least-significant bit at the top,

and the most-significant bit adjacent to the control block at the bottom. New

keys arrive at the left-hand side, and will “ripple” to the right, as they are

compared with stored keys until they fall into the correct column. Each control

block, of which there is one per key, simply uses the result of the arithmetic

comparison made above:

if the stored key (S) is smaller

than the one to its left (L), key L is passed to the cell on the right, i.e.

bypassing S. otherwise, L must be stored in place of S, and S passed to the right.

Figure 5–26 shows the data flow for the

comparator cell, as implemented in Algotronix CAL logic. When all the keys have

been submitted, the sorted list is returned by a series of left shifts, that

is, so the smallest key emerges first.

Figure 5–25. Systolic

sorter.

Figure 5–26. Sorter

comparator cell—data flow.

In every column an arithmetic

comparison is made, commencing with the less–significant bit at the top of the

key. Each bit stage generates a signal “less,” which indicates that, based on

the series of bits so far, the stored key is less than the one to its left.

This result may change as the more significant bits are considered. The

comparator logic is illustrated in

Figure 5-27, and is described as follows:

Figure 5–27. Sorter

comparator cell. Comparison logic.

if the left-item bit and the

stored bit are equivalent, pass on the “less” result from the Is comparator

above. otherwise, if the left-item bit is a 1, set “less” to 1 or if a 0, then

set “less” to 0.

It is implemented in the 1-bit

comparator shown in

Figure 5–28.

The control block is shown in

Figure 5–29. Before sorting starts, the

CLRb signal sets all the D flip-flops to 1, and as keys appear, Os are

propagated through the control blocks. When the set of keys to be sorted has

been entered, the results are retrieved in an ascending order by issuing a set

of “read” instructions, which shift the contents of the control and key blocks

left.

Figure 5–30 shows an overall view of the

sorter.

5.6 MULTIPLIERS

Multiplier designs are a simple way of

studying different varieties of digital logic designs. It is possible to develop

different multiplier examples to study the varieties of design approaches and

implement these designs using FPGAs. In the following sections Xilinx 3000

implementations are assumed, but the approaches vary from fully automated to

handcrafted with corresponding gains in performance.

5.6.1 Parallel

Multipliers

The simplest of the multiplier designs

is a parallel-combinational logic multiplier. This multiplier produces a result

by adding the partial products of equal binary weight with the carries of the

lower binary weight. The design consists simply of AND, OR, XOR, and inverter

gates at the top-level schematic.

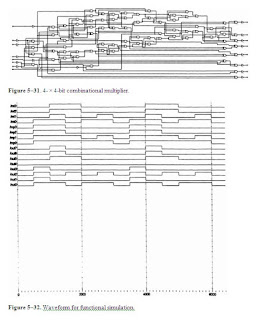

Schematic Entry Figure 5-31 is an example of a 4- × 4-bit

combinational logic multiplier. The design was created using ViewLogic

WorkView.

Using CAD tools, a logic design can be entered directly as a top-level

schematic, manually connecting gates together. To obtain more information about

creating a schematic design, refer to the current Xilinx and/or Viewlogic

WorkView

manuals.

Functional

Simulation It is always a good idea to check the

design functionality before actually continuing with the creation of the layout

file. The software used to create the schematic design provided support for a

functional simulation of the schematic circuit. Refer to

Figure 5–32.

Figure 5–28. Comparator.

CAL block.

Figure 5–29. Control: CAL

block.

Figure 5–30. Overall layout

of sorter.

Figure 5–31. 4- × 4-bit

combinational multiplier.

Figure 5–32. Waveform for

functional simulation.

File-conversion Process

In order to be able to create a Xilinx layout for the parallel multiplier, it

is necessary to follow a series of steps to convert the file to the correct

format. The file-conversion process consists of the following steps:

- Generate

a “wirelist” (net) file from the schematic level file

- Generate

a netlist file from the wirelist file

- Generate

a layout file using the automatic router

Speed Most

of the technology used today requires the use of high-speed circuits. The speed

performance of the Xilinx design will be affected by several factors: choice of

part being used, the arrangement of the programmed logic within the circuit,

and the efficiency of the layout itself.

XACT Design Entry It

is possible to enter a design directly by using

XACT (the Xilinx design editor).

This can be done by configuring the blocks directly, using logic expressions

instead of entering a schematic.

Figure 5–33 gives an example of the

multiplier as entered using

XACT.

5.6.2 Serial

Multiplier with Parallel Addition

Another example of a multiplier

circuit is a serial multiplier. The main difference between the parallel logic

multiplier and the serial multiplier is the introduction of memory and timing

in the design.

Schematic Entry Figure 5–34 is a schematic for a serial

parallel multiplier created using ViewLogic

WorkView.

The serial multiplier can be

processed as before to generate the Xilinx layout file.

Figure 5–35 shows the serial multiplier

layout configuration for a 3000 family Xilinx chip.

5.7 A

PARALLEL CONTROLLER DESIGN*

An outline of the design and

implementation of a video framestore design is presented that used the Petri

net method described in

Chapter 2, and is implemented on a Xilinx

LCA.

The function of the framestore

is to receive or transmit digital video data from a memory in a raster scan

format. Region of interest (ROI) is supported, allowing the reception and

transmission of frames of any size. Video data arrive on a 16-bit-wide bus

every 100 ns. A frame synchronization signal defines the start of a field of

data of 260 lines by 760 pixels. Each line starts with a horizontal

synchronization signal. The video controller has to deposit the data in a video

framestore in the correct order (interleaving two fields to create a full

frame) and to manage accesses to the memory. A second independent video channel

operates at the same time, but it must access a different block of memory. A

transputer is able to access both memory blocks while video operations are

being performed. At the end of a frame, the video channels may be required to

switch memory banks, and this must be handled by the controller.

Figure 5–33. XACT

view of the parallel multiplier.

The controller has a number of

registers containing its operating parameters, such as horizontal start and end

count, vertical start and end count, and start address in memory.

Figure 5–36 shows the datapath structure of

the controller design. It contains all the datapaths and a large Petri net

controller and has been implemented in a Xilinx 3090 FPGA.

Figure 5–34. Schematic for

the serial multiplier.

Figure 5–35. XACT

configuration for the serial multiplier.

5.7.1 Operation

of Part of the Petri Net Controller

The controller Petri net uses

inhibiting and enabling arcs and is made up of many small linked Petri nets. To

illustrate both the Petri net technique and its use in hardware design, a small

fragment of the controller is described.

Figure 5–37 shows the parts of the

controller associated with generating the horizontal synchronous output signal,

‘HsyncOut’, and with determining the position of active pixels within a line.

Consider that the circuit is initially idle, and is to be operated as a timing

master, with ‘HsyncOut’ connected back to the controller’s ‘Hsync’ input.

Although ‘Hsync’ is not directly used in this part of the circuit, its

assertion will cause the external pixel counter, ‘Hctr’ in

Figure 5–36, to be reset and thereafter to

count toward the register values ‘Hstart’ and ‘Hend’, so that the Petri net

inputs ‘HctrAtHstart’ and ‘HctrAtHend’ are asserted at the appropriate times.

Figure 5–36. Simplified

block diagram of the MAXbus controller.

An image transfer is initiated

when an “arming” transition fires in another part of the net, causing a token

to arrive in P3. This token is removed on the next clock cycle, so that the

arming signal is only one cycle wide. The arming signal enables transition T4,

so that on the next clock cycle T4 fires, removing the token in P4 and thereby

releasing the “done” output to indicate that the controller is running. The

arming signal also enables transition T1 so that on the next clock cycle the

token in P2 moves to place PI, asserting ‘HsyncOut’. Having no other associated

conditions, transition T2 will immediately fire on the following clock cycle,

returning the token to P2. ‘HsyncOut’ is thus one cycle wide.

As mentioned earlier, the

generation of the ‘HsyncOut’ signal causes the pixel counter to be cleared, and

to count toward ‘Hstart’ and ‘Hend’. When ‘Hctr’ reaches ‘Hstart’,

‘HctrAtHstart’ is asserted, T5 fires, and ‘Hblank’ becomes inactive. External

circuitry (the serial clock in

Figure 5–36) uses this signal, together

with a ‘Vblank’ signal generated elsewhere, to decide whether to clock active

data. Later, ‘HctrAtEnd’ is asserted and T6 fires, reenabling ‘Hblank’. The

assertion of ‘HctrAtHend’ also has the effect of firing transition T3, thereby

generating a further ‘Hsync’ output from place PI, to indicate the start of a

new line. The process continues until a token arrives at P4 indicating that the

sequence is done and this inhibits T3 from firing.

Figure 5–37. A small part

of the controller.

5.7.2 Characteristics

of the Design Technique

It can be seen that the small ‘Hblank’

circuit lies in a separate Petri net running in parallel with the rest of the

circuit. The introduction of parallelism in this conventional way is over and

above the parallelism that can be expressed within a Petri net. Parallelism is

used in the circuit both to have more than one task running at a time and

simply to express the design more easily. In the case of the ‘Hblank’ circuit,

this convenience allows the implementation to be a natural expression of the

definition of horizontal blanking, taking place from the end of one line to the

start of the next.

5.7.3 Implementation

on XC3090

The design was entered in schematic

form to the ViewLogic CAD system. Four designs have been produced: an 8-bit

design and a 16-bit design, each with and without ROI capability. These have

all been simulated using nominal delays for the logic cell array (LCA) circuit

components.

The full 16-bit design uses 83%

of the 320 CLBs and 86% of the 144 IOBs available. This design could not be

routed automatically on the tools available at the time (1991). An early effort

to cut down the design to 68% CLB usage also proved to be unroutable using

automatic tools. For comparison, an inoperable version with 50% CLB usage was

routed automatically. With smaller array parts, automatic routing was

successful at 80% CLB usage. However, it was clear that the place-and-route

strategies in the software could not cope satisfactorily with the larger

arrays.

These problems were overcome

using informal tools from Xilinx for routing a functional block at a time. This

system allows the designer to carry out floor planning, leaving space for

routing channels, which the automatic tools cannot do. The automatic router is

then run on the small blocks, where it manages to achieve a higher packing

density. Each iteration adds one functional block to the work already routed;

earlier routing is copied into the current iteration using the place-and-route

program’s (APR) guide option. Manual intervention, using the XACT LCA editor

program, is needed to tidy up the design at each stage. The newer design tools

from the manufacturer more adequately deal with these problems, as will be seen

shortly.

As a result of this experience the

following hints are offered for future users:

- Supplement

long lines by routing out on one side of the chip and back in the other

side.

- Bring

signals used in a number of places into the chip using multiple pins.

- Minimize

three state buffer usage as they reduce access to nearby CLBs.

- Minimize

use of the RD and CKEN pins on CLBs, as these cannot be swapped to other

locations in the way that, say, X and Y can, to make routing easier. The

exception is when driving a number of these pins from the same long line.

- When

using outer long lines to drive, the three state input to IOBs indicate

this to the router with a small piece of manual prerouting.

Two further problems were

encountered. The first arises when routing a block that has a pin that is to be

connected to another block that has yet to be routed. The pin can become buried

with no access path to it. To overcome this a dummy circuit is added, using XACT,

connecting to such pins, thereby forcing a route to be found before the current

iteration can be declared complete.

The second problem arises when

copying routing information from a previous iteration. During the routing

process CLB pins are swapped about to make routing easier. When copying routing

information from the previous iteration, the router attempts to repeat the pin

swaps already decided on. However, it occasionally fails, believing the pin

swaps to be illegal (which they sometimes are until other pin swaps have been

done first). This is tiresome, especially when it involves the loss of routing

done manually. When the problem is observed, the solution is to return to the

circuit diagram and lock the correct pin designations in place.

During the time of preparing

this book, there have been substantial improvements in computer-aided design

support. Following the successful completion of the original design at Bristol

University in 1991, the design files were made available to Direct Insight Ltd.

(U.K.). In 1993 the design was completed using NeoCAD software for Xilinx

FPGAs, and with the aid of a 50 MHz PC486 computer. The standard

placement-and-routing package was run with 100 cost tables. No timing

constraints were specified, and so the system ran without timing optimization.

After 108 hours, it had tried 64 cost tables, and one of these resulted in a

fully-routed chip, taking 1 hour and 25 minutes. Twenty-eight had less than 10

nets unrouted, and human intervention could probably have quickly resulted in

other fully-routed options. The fully-routed version was run through five

cost-based clean-ups and five delay-based clean-ups, taking a further 18

minutes. The design achieved a 6.3 MHz clock rate. Following further routing

iterations over 24 hours, the clock rate had increased to 7 MHz. This is

comparable with the existing design, which operates reliably at 6.75 MHz. A

layout for the final NeoCAD design is shown in

Figure 5–38.

In 1994 the current production release

of Xilinx software XACT 5.0.0 was run with XACT-Performance enabled, so that

the resulting circuit would run at its highest speed. After 82 hours on Sun

Microsystems SPARC 10 workstations, the system had generated 11 full-routed

designs out of 16 attempts. The first fully-routed result was available after 1

hour and 49 minutes. The varied results were produced by selecting different

placement parameters, including the placement “seed” and “placer effort.” The

clock rates for fully-routed chips varied from 5.4 MHz to 6.9 MHz. Six of the

11 fully-routed designs performed at 6.0 MHz or faster. The best two results

gave speeds of 6.8 and 6.9 MHz, which compare favorably with the existing

design (6.75 MHz). A layout for the fastest Xilinx design is shown in

Figure 5–39.

Figure 5–38 Final NeoCAD

design for the parallel controller.

5.7.4 Conclusions

The full 16-bit version of the

controller was eventually routed. While in 1991 this took over four months of

continuous effort, more recent CAD software allows rapid completion of quite

complex designs to specified performance criteria. An 8-layer printed-circuit

board has been designed and manufactured, and there are now more than 25 copies

of the design in routine use.

SUGGESTIONS FOR

PROJECTS

- Faster

adder circuits based on carry-lookahead logic [Wakerly90]. Note

that the Xilinx 4000 series incorporates carry-lookahead logic in its

CLBs.

- Arithmetic-logic

unit, (see [Wakerly90]).

- Design

an elementary processor, (see [Segee91]).

- Adapt

the sorter design for another FPGA family.

- Boundary

Scan. Boundary Scan testing has recently become standard, and considerably

simplifies testing both chips and their printed circuit board environment.

See [Maunder90] for

details.

- Dynamic

memory controller. Dynamic memory requires periodic refresh to avoid loss

of contents. For example, the Intel 4116 16K DRAM is organized as 128 rows

and 128 columns. Each row can be read and rewritten in a single cycle, and

each must be visited every 2 ms.

- Asynchronous

serial data transmission and reception. The RS232 standard defines start

and stop bits for the 8-bit characters. Using a clock running at 4 times

the nominal baud rate, it is possible to sample the incoming bits

correctly. The transmitter design is simpler than the receiver.

- Manchester-coded

data transmission. Manchester coding carries both data and timing

information on the same channel, and the edge transitions in each bit time

allow a receiver to adjust its clock by speeding up or slowing down from

the nominal bit rate. The receiver design calls for a phaselocked loop,